BERINGER WHEELS: advanced technology

- High strength aluminum alloy machined from solid on CNC, anodized for optimal corrosion resistance.

- TUBELESS wheel with O-rings and rigid valve.

- SEALED BALL BEARINGS for optimal durability: greased for life, no maintenance.

- Very low rolling resistance.

BRAKE CALIPERS:

- covered by AEROTEC® Patents

- 2 or 3 stainless steel polished pistons

- body made of aerospace alloy to withstand high temperatures (>200Mpa at 200°C)

- available for DOT4 fluid OR for MINERAL (MIL FLUID) (seals are different; specify and never mix)

- 2 inputs, thread size M10x1

- full metallic brake pads (no rivets) for extended life

- covered by AEROTEC® patents

- stainless steel disc or high strength steel disc with coating

- brake discs are made of highest quality material for thermal stability and long life

How to choose your wheel & brake system:

- Select the size of tire that you need.

- Then select the wheel size required for this tire (use our application chart page 18).

- Check the static load rating: this is the weight on each wheel (at maximum static aircraft weight) that the wheel is capable of supporting.

- Check the kinetic energy rating: the first function of a brake system is to transform aircraft kinetic en-ergy into heat. This heat is absorbed and dissipated mostly by the disc (a thicker disc will absorb more heat energy).

5″ WHEEL & BRAKE – STANDARD SERIE

- static load rating of 1,430 lbs (650kg)

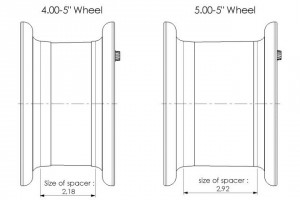

- sizes: 5.00-5 and 4.00-5

- 2 piston standard brake

- lightweight stainless steel disc

- suitable for LSA and gliders

5″ WHEEL & BRAKE – HE SERIESTSO & ETSO

- static load rating of 1,430 lbs (650kg)

- sizes: 5.00-5 and 4.00-5

- HE caliper 2 piston with cooling thins

- + 40% braking torque

- 2 types of high strength discs

- insulated full metallic brake pad

- caliper EA-002: for 2 seat aircraft (RV’s, Aerobatic)

- caliper EA-002.2 (thicker disc): for high landing speed aircraft (Lancair, Glasair,…)

6″ WHEEL & BRAKE – SL SERIES

- these new SL wheels were designed with the new technology improvements made possible thanks to the BERINGER static and dynamic test benches

- static load rating increased up to 935 lbs (425kg) to fit Aircraft up to 850kg (gross weight)

- designed in 2 parts instead of 3

- they are even more lighter: -200g per wheel (RF-009)

- easy maintenance: only 1 o’ring seal

- sizes: 4.00-6 and 6.00-6

- 2 piston standard brake

- lightweight stainless steel disc

- suitable for ultra light aircraft and LSA

6″ WHEEL & BRAKE – HE SERIESTSO & ETSO

- static load rating of 2,090 lbs (950kg)

- size: 6.00-6

- HE caliper 2 piston with cooling thins

- doubled braking torque compare to SL series

- 2 types of high strength discs

- insulated full metallic brake pad

- caliper EA-003: for 2 seat aircraft (Taildragger, Champion,Glasair)

- caliper EA-003.3 (thicker disc): for 4 seat aircraft (Lancair IV, Cirrus SR20)

- caliper EA-003.4: dual caliper for increased braking torque: ultra short braking distance, suitable for Cirrus SR22, DA42,…

| Assy part no |

Certification | Size | Static load kg |

Limit load kg |

Caliper part no |

Disc part no |

Braking torque inch.-lbs |

Max RTO energy ft-lbs |

Weight kg |

|---|---|---|---|---|---|---|---|---|---|

| ROUES 5″ – série STANDARD | |||||||||

| RF-002 | – | 5.00-5″ | 650 | 2600 | EA-006 | DSC-006 | 2,450 | 140,000 | 1.977 |

| RF-007 | – | 4.00-5″ | 650 | 2600 | EA-006 | DSC-006 | 2,450 | 140,000 | 1.881 |

| cap | – | – | – | – | – | – | – | – | 0.030 |

| ROUES 5″ – séries HE | |||||||||

| RF-005 | TSO | 5.00-5″ | 650 | 2600 | EA-002 | DSC-008 | 3,500 | 210,000 | 2.445 |

| RF-005 | TSO | 5.00-5″ | 650 | 2600 | EA-002.2 | DSC-008.2 | 3,500 | 361,000 | 2.681 |

| RF-012 | – | 4.00-5″ | 650 | 2600 | EA-002 | DSC-008 | 3,500 | 210,000 | 2.318 |

| RF-007 | – | 4.00-5″ | 650 | 2600 | EA-002.2 | DSC-008.2 | 3,500 | 361,000 | 2.590 |

| cap | – | – | – | – | – | – | – | – | 0.030 |

| ROUES 6″ – SL | |||||||||

| RF-009 | – | 6.00-6 | 425 | 1500 | EA-006E | DSC-006 | 2,450 | 140,000 | 2.080 |

| RF-004 | – | 4.00-6 | 425 | 1500 | EA-006E | DSC-006 | 2,450 | 140,000 | 1.940 |

| cap | – | – | – | – | – | – | – | – | 0.030 |

| ROUES 6″ – séries HE | |||||||||

| RF-006 | TSO | 6.00-6″ | 950 | 3400 | EA-003 | DSC-009 | 4,900 | 355,000 | 3.772 |

| RF-006 | TSO | 6.00-6″ | 950 | 3400 | EA-003.3 | DSC-009.3 | 4,900 | 500,000 | 4.136 |

| RF-006 | TSO | 6.00-6″ | 950 | 3400 | EA-003.4 | DSC-009.3 | 9,800 | 550,000 | 4.909 |

| cap | – | – | – | – | – | – | – | – | 0.030 |

| ROUES 8″ | |||||||||

| RF-010 | – | 18×5.5 | 1250 | 4375 | EA-008 | DSC-012 | 8,300 | 1,115,000 | 7.600 |

| ROUES 10″ | |||||||||

| RF-011 | – | 24×7.7 | 1400 | 3710 | EA-001 | DSC-011 | 16,900 | 845,000 | 11,400 |

| ROUES 12″ | |||||||||

| RF-003 | – | 11.00-12″ | 1400 | 3710 | EA-001 | DSC-011 | 16,900 | 845,000 | 14.100 |

| CAUTION: static load valid only with appropriate tire | |||||||||

We recommend first mounting of tires on wheels in our plant. This service, free of charge, includes a pressure test, ensuring maximum security of the assembly.

FINISH: Red anodizing is standard color for wheels, brakes and master cylinders. Other colors are available on special order with an extra delay at an additional cost per batch of parts: silver, black, yellow, titanium grey. Colors may vary..